Adsorption Dryers F-DRY

The F-DRY range of adsorption dryers has been developed to separate moisture from compressed air, thereby reducing the dew point of the system. These dryers consist of two columns filled with desiccant, a controller with LCD screen, valves, pressure gauges, a base and filters fitted with the appropriate filter element. Adsorption takes place under pressure in the first column while, at the same time, the second regenerates using a small portion of air that has already been dried. When the first column is saturated to a certain level, it switches over and the adsorption process continues in the second column without any pressure drop. The saturated adsorbent can be regenerated using a small amount of air that has already been dried and decompressed. This extremely dry and decompressed air, also known as "purge air", is then injected into the saturated column, in the opposite direction, in order to eliminate the adsorbed water molecules and release them.

Characteristics

- Operation pressure: 4 to 16 bar

- Functioning temperature: 1.5 to 50 ℃

- Dew point under pressure: -40 ℃ (-25 ℃/-70 ℃)

- Flow: 1200 to 6500 Nm³/h

- Standard color: RAL 5012

- Average compressed air consumption: 15 - 20 %

Applications

- Compressed air systems

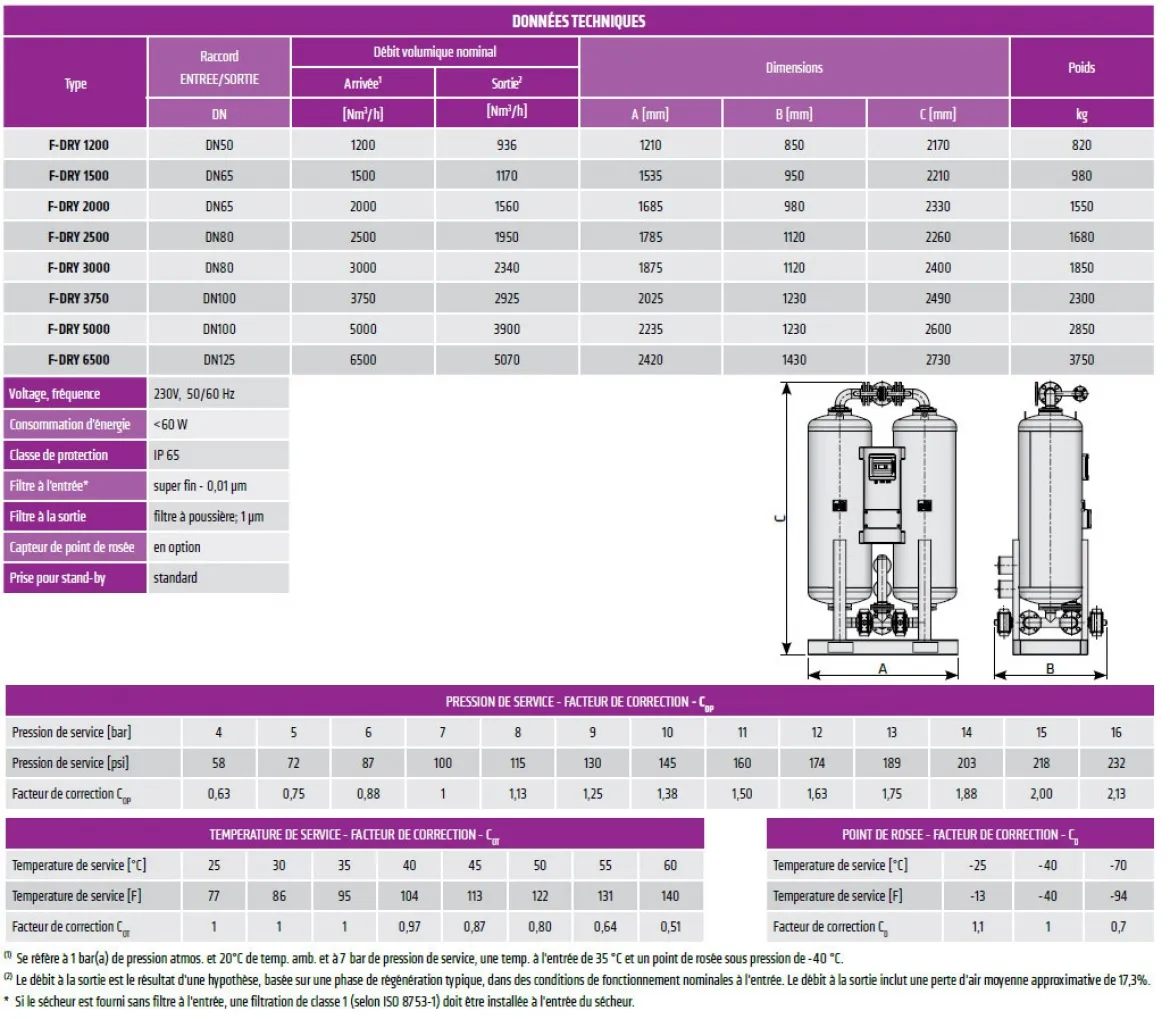

Technical sheet