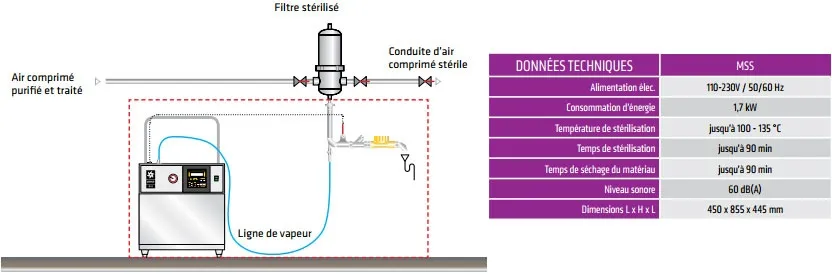

MSS sterillisers

Piping with high-temperature, moisture-saturated compressed air is a suitable environment for microbial growth. To stop this happening, filters need to be sterilised. Sterilisation can be carried out on site or by autoclaving. For the latter, the filters must be removed from the system but, because of the septic conditions in the atmosphere, it is difficult to avoid contamination when reinstalling them. Sterilization In Place (SIP, the practice of sterilizing a component without removing it from its installation) guarantees better results and is more common in the process industry. Steam sterilisation is an effective method of stopping microbial activity. The "mobile steam steriliser" is designed for easier, cheaper and faster MSS. The MSS can be easily connected to any part of the plant where sterilisation is required. Once filter sterilisation is complete, the MSS can simply be unplugged and transported to another location.

Characteristics

- Pressure: 1 to 3.6 bar

- Operation temperature: 100 to 135 ℃

- Sterellisation duration: up to 90 minutes

- Drying duration: up to 90 minutes

Applications

- Alimentation

- Dairies

- Small brasseries